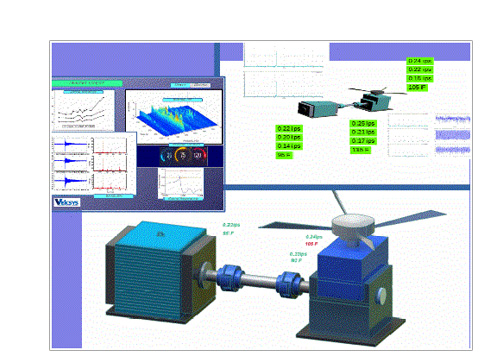

The IVS ‘Watchdog’ feature monitors your equipment full-time. ‘Watchdog’ acquires a full set of PdM quality data upon alert – in addition to regular data. Rather than running out to take data on alert, take decisive action and step briskly ahead for the solution. IVS ‘Watchdog’ feature sends you instant email alerts to keep you ahead of those short-term events and quickly developing faults.

Cooling Towers

Prevent unexpected cooling tower failures while increasing plant efficiency

Cooling tower failures are expensive and most monitoring and maintenance programs don't give the advance warning you need. Standard walk arounds, visual inspections, and reactionary maintenance programs are based on assumptions, trend extrapolations, and unwieldy 'too far in the past' data.

The resulting delay before degradation issues such as worn bearings, poor oil quality, damaged shafts or excessive vibrations become known mean that cooling tower failures are often too close to avoid catastrophic failures and its compounding expense and inconvenience.

Who wants the unplanned downtime while emergency repairs are carried out?

Who needs the costly delays and interruptions to production while parts are being sourced?

Wouldn't it be so much better if you could understand the real state of cooling tower components before issues arise?

Wouldn't your plant run more smoothly if you could plan for the future by anticipating the parts needed then scheduling maintenance during preferred periods? Yes, of course. And with timely data, information, and decision tools you can.